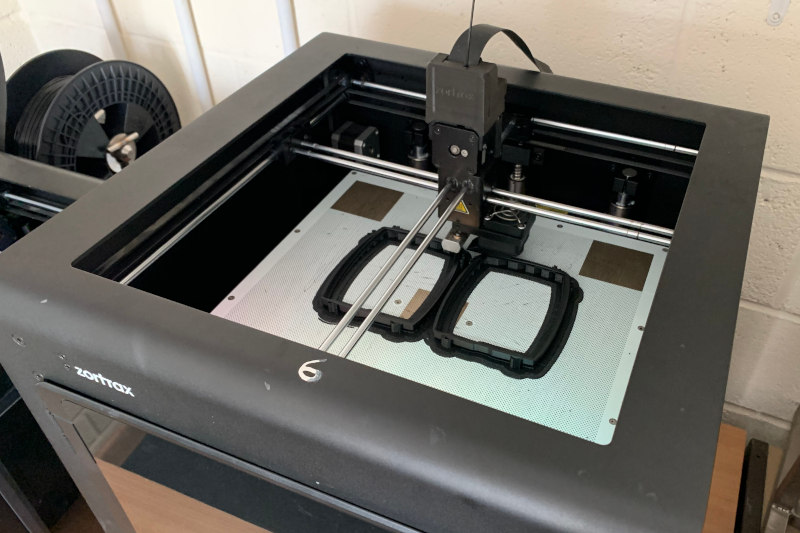

3D printing service

Exactly to your needs

- Prototyping

- Low volume products

- End use parts

- Architecture modelling

- Medical models

- Figurines and Game models

- Automotive research and development

Quality

Printing terms

Our FDM 3D printers work in LPD technology, which is the most cost-efficient for making simple medium size products in large quantities.

What is FDM?

What is LPD?

We use a variety of filaments such as ABS, HIPS, PLA, Nylon and more

ABS is a real expert in durability. Prints made using this filament are characterized by their hardness and high impact resistance. They are also resistant to high temperatures and abrasion. These properties extend the possibilities of ABS application.

The advantages of ABS will certainly be appreciated by designers and engineers. The prints can be used to create concept models for new products or even their final versions. ABS can also be used in production, especially in prototyping more rigid elements.

Applications:

- Prototypes: linking elements, elements which require high temperature resistance

- Tools or their elements: gears, racks, elements which require high durability

- Gadgets or their parts: phone cases, stands, keychains

- Toys: bricks, robots or their parts, car elements

- House equipment: hangers, flower pots, vases